If you are interested in our products ,please contact our team

In the world of mechanical engineering and design, gas springs play a crucial role in facilitating smooth motions and supporting weight in various applications. From automotive to furniture and medical equipment, the versatility and efficiency of gas springs cannot be overstated. This comprehensive guide aims to shed light on the different types of gas springs, focusing on their structure, function, and application. Let’s delve into the world of gas springs, exploring each type in detail.

Before we explore the different types, it's essential to understand what gas springs are and how they operate. A gas spring is a type of spring that, unlike traditional mechanical springs, uses compressed gas contained within a cylinder and compressed by a piston to exert a force. Gas springs are designed to apply force linearly and can be found in a vast array of applications, providing an elegant solution for balancing weight, controlling motion, and ensuring safety.

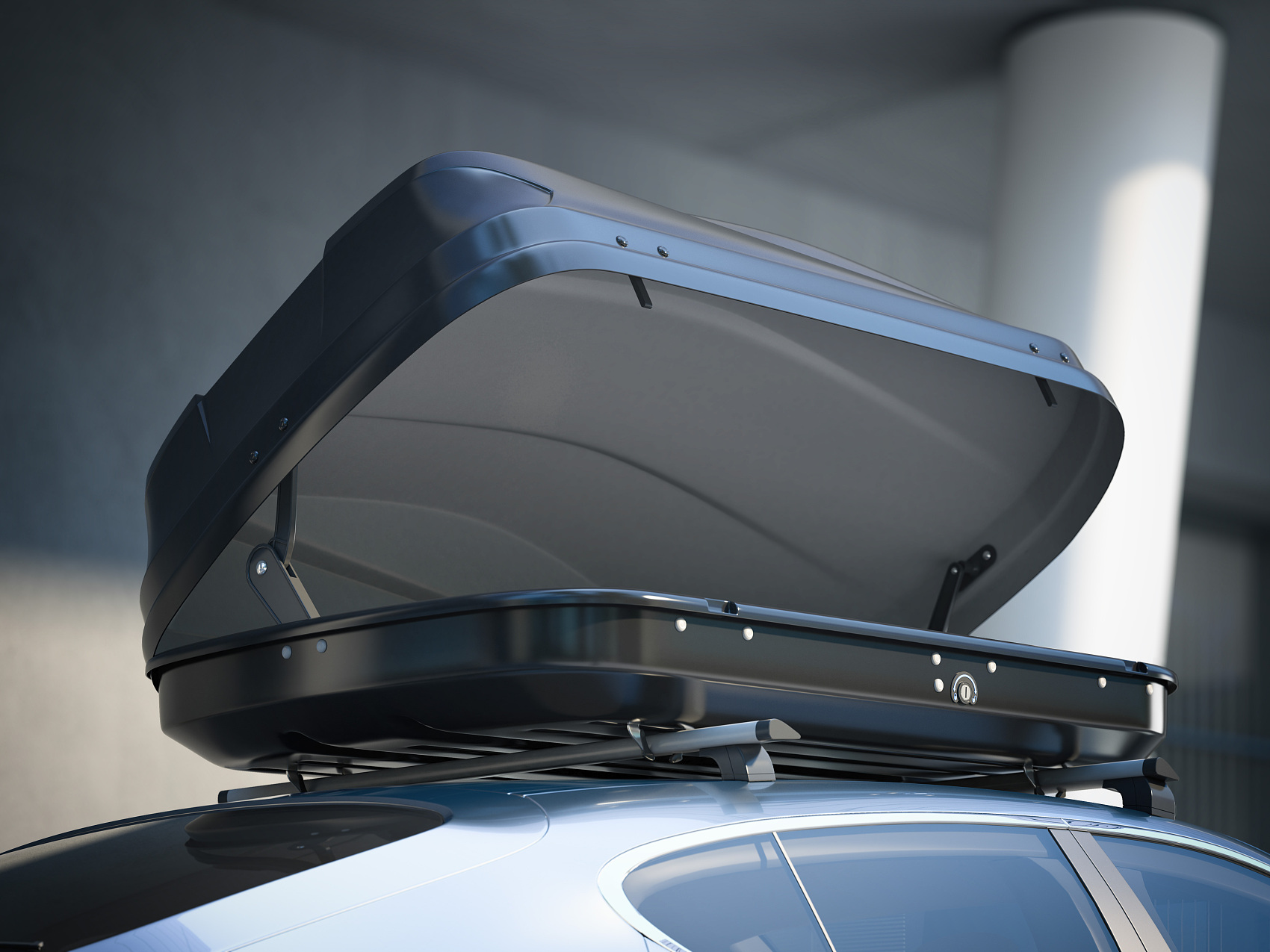

Free gas springs are the most basic type of gas springs. They consist of a cylinder filled with nitrogen gas and a piston that moves freely within the cylinder. The pressurized gas exerts a force on the piston, creating a push or pull motion, depending on the design. These gas springs are commonly used in automotive applications, such as the lifting mechanism for trunk lids and hoods, as well as in office chairs, where they aid in height adjustment.

Self-locking gas springs incorporate an additional locking mechanism that allows them to hold a specific position without external support. This feature is particularly useful in applications where safety or precision positioning is crucial. For instance, adjustable hospital beds and ergonomic furniture often utilize self-locking gas springs to maintain desired positions securely.

Unlike the more common compression gas springs, traction gas springs work by pulling rather than pushing. When the piston rod is pulled out, the internal pressure decreases, and the spring exerts a pulling force to return to its original position. Traction gas springs are particularly effective for applications requiring controlled retraction, such as in doors, hatches, or even in certain types of retractable screens.

Random stop gas springs, also known as locking or variable position gas springs, can be stopped at any point in their travel. This unique feature is made possible by a specialized mechanism that allows the gas spring to lock when the piston rod is depressed and then unlock when the rod is slightly extended. They're ideal for applications requiring multiple or adjustable stopping positions, such as adjustable desks, monitors stands, and various ergonomic products.

Swivel chair gas springs are specifically designed for use in office chairs. These gas springs not only allow for height adjustment but also incorporate a swivel feature that enables the chair to rotate freely. The integration of gas spring technology in office chairs has revolutionized ergonomic design, providing comfort and adjustability to countless workplaces.

Air pressure rods, often mistaken for traditional gas springs, utilize air as the working medium instead of nitrogen gas. These rods are typically used in lighter applications where less force is required, such as in certain types of small furniture or appliances. While they operate on a similar principle to gas springs, the primary difference lies in the medium used and the application's specific force requirements.

Dampers are a type of gas spring designed to absorb and dissipate energy. They are primarily used to control the speed of movement in various applications, such as soft-closing cabinet doors or to stabilize heavy equipment during transportation. By regulating the flow of gas through internal orifices, dampers provide a smooth, controlled motion, enhancing safety and functionality in many products.

Gas springs are a fundamental component in numerous applications, providing solutions for lifting, holding, and moving loads with precision and ease. From free gas springs to dampers, each type offers unique benefits tailored to specific requirements. Understanding the different types of gas springs and their applications is crucial for designers, engineers, and consumers alike, enabling the selection of the most appropriate gas spring for any given task. As technology evolves, so too will the capabilities and applications of gas springs, continuing to improve the functionality and safety of various products and machinery.

In conclusion, whether it's providing the lifting force for an automotive trunk, enabling the height adjustment of an office chair, or ensuring the smooth closing of a cabinet door, gas springs play an indispensable role. By offering a reliable and efficient means of managing motion, gas springs enhance the usability and longevity of products across a myriad of industries.