If you are interested in our products ,please contact our team

In the dynamic world of motion control, adjustable gas springs play a pivotal role across several industries, including automotive, furniture, and healthcare. These innovative components leverage the fundamental principles of pneumatics to offer a versatile and user-friendly solution for managing and assisting movements of various mechanical assemblies. This article aims to demystify the technology behind adjustable gas springs, elucidating their working principles, benefits, and applications to provide you with an all-encompassing understanding of this indispensable tool.

Understanding Adjustable Gas Springs .

At its core, an adjustable gas spring is a self-contained pneumatic device capable of exerting force or supporting weight using pressurized gas. Enclosed within a cylindrical housing or tube, this apparatus consists of a piston attached to a rod, which moves in and out of the cylinder body. The adjustability feature allows users to modify the force exerted by the spring, making it exceptionally versatile for various applications.

How Adjustable Gas Springs Work

The operation of an adjustable gas spring hinges on Pascal's law, which posits that pressure exerted on a confined fluid is distributed undiminished in every direction throughout the container. Here’s a step-by-step breakdown of its functionality:

1. Compression and Pressure Equalization: When force is applied to the rod, causing it to retract into the cylinder, the volume within the cylinder decreases, leading to an increase in gas pressure. This high-pressure gas exerts force on the piston, which is transmitted through the rod, providing the necessary motion or support.

2. Extension and Controlled Movement: Removing the external force allows the high-pressure gas to expand, driving the piston and rod outward. The speed of this extension is controlled by an adjustable orifice or valve, which regulates the flow of gas into and out of the piston area, ensuring smooth operation.

3. Adjustability: The unique feature of adjustable gas springs lies in the user’s ability to regulate the spring force. This is achieved by varying the pressure of the gas within the cylinder. Typically, a valve at one end of the spring allows for the addition or release of gas, thereby adjusting the internal pressure. By increasing the gas pressure, the force exerted by the spring can be amplified, and conversely, reducing the pressure lowers the force.

Benefits of Adjustable Gas Springs

Versatility: Whether it is lifting a heavy trunk lid or adjusting the height of an ergonomic office chair, the force of an adjustable gas spring can be precisely tuned to meet the specific requirements of diverse applications.

Smooth Operation: The controlled movement provided by adjustable gas springs ensures a smooth and consistent operation, enhancing user experience by eliminating abrupt or jerky movements.

Safety and Reliability: With no external power source or complex machinery involved, adjustable gas springs offer a safe and reliable solution for managing movements and supporting weights.

Ease of Installation: The compact and self-contained design of gas springs allows for easy installation and maintenance, making them an attractive option for both manufacturers and end-users.

Applications of Adjustable Gas Springs

The versatility of adjustable gas springs makes them indispensable in various sectors:

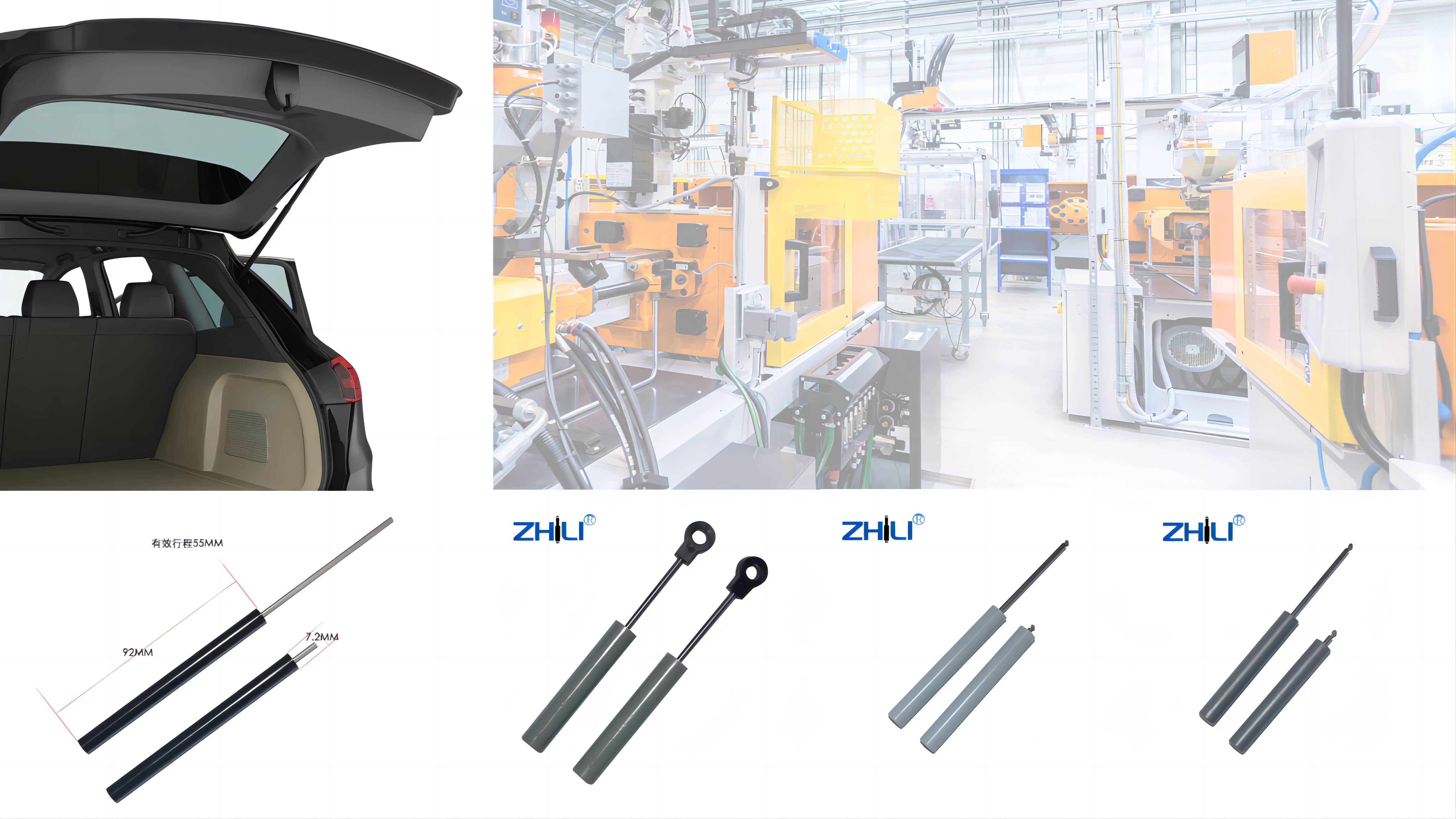

Automotive: Used in tailgates, hood lifts, and adjustable seats to provide controlled movement and support.

Furniture: Implemented in reclining chairs, adjustable beds, and cabinet doors to facilitate smooth operations.

Industrial Machinery: Employs adjustable gas springs for counterbalancing or assisting movements in machinery and equipment.

Healthcare: Found in hospital beds, examination chairs, and medical devices to adjust positions with precision and care.

Choosing the Right Adjustable Gas Spring

Selecting an appropriate gas spring involves considering the following factors:

Force Requirement: Assess the force needed for your application to select a gas spring with suitable pressure adjustability.

Stroke Length: Determine the required movement range to choose a gas spring with an adequate stroke length.

Mounting: Evaluate the space and mounting options in your application to ensure compatibility.

Maintenance Tips

While adjustable gas springs are designed for durability, regular maintenance ensures optimum performance. Periodically checking for leaks, ensuring clean mounting points, and adjusting gas pressure as needed will prolong the life of these components.

Conclusion

Adjustable gas springs represent a pinnacle of engineering innovation, offering a blend of functionality, reliability, and versatility unmatched by traditional mechanical sp