If you are interested in our products ,please contact our team

In the vast expanse of mechanical engineering, controlling vibration and motion is critical for enhancing the performance and longevity of machinery. Among the plethora of solutions devised to tackle this issue, metal dampers stand out as a pivotal component in modern mechanical devices and vehicles. This blog post aims to unpack the subtleties of metal dampers, exploring what they are, how they function, and the vital role they play in various applications.

At its core, a metal damper is a device designed to absorb and dissipate kinetic energy from mechanical systems, thereby minimizing the impact force of moving elements. These components are crucial in controlling vibration, shock, and noise levels within machinery, contributing significantly to the stabilization of mechanical operations. Metal dampers work by converting the kinetic energy of moving parts into heat, typically through friction or fluid resistance, which is then dissipated into the environment.

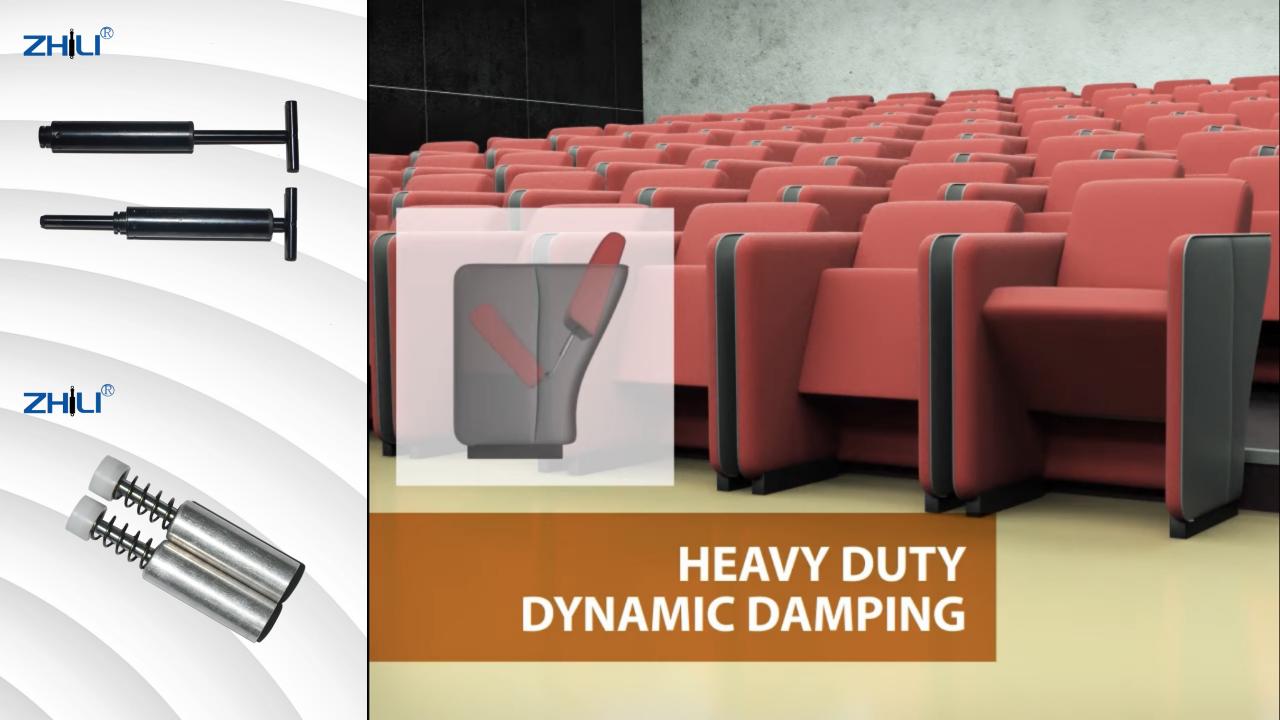

Metal dampers are categorized based on the direction of damping they provide: compression, extension, and both push-in and pull-out.

Compression Damping: This refers to the resistance a damper provides against compressive forces, effectively slowing down the motion in the direction of compression.

Extension Damping: In this type, the damper provides resistance to extension forces, controlling the motion as it expands or stretches.

Bi-directional Damping: Some dampers are designed to provide damping in both compression and extension directions, offering a versatile solution for a wide range of applications.

The choice among these types depends on the specific requirements of the machinery or system in which the damper is to be incorporated.

Metal dampers are not just additional components; they are indispensable for the proper functioning of mechanical systems. Their ability to mitigate vibration and convert friction into internal energy plays a pivotal role in driving the operation of various devices. By reducing the wear and tear caused by uncontrolled movement, dampers extend the lifespan of machinery and contribute to safer and more efficient operation.

The utilities of metal dampers are vast and varied, manifesting in numerous sectors including automotive, aerospace, industrial machinery, and consumer electronics, to name a few. In vehicles, for instance, they are used to enhance ride comfort and vehicle stability by minimizing vibrations. In industrial settings, dampers protect machinery and sensitive components from damage caused by excessive movement or shock forces.

Advancements in materials science and engineering have led to the development of more efficient and durable metal dampers. Innovations such as viscoelastic metal dampers and magneto-rheological dampers showcase the industry's move towards adaptive and responsive damping solutions, capable of adjusting to changing dynamic conditions in real-time.

These dampers utilize viscoelastic materials sandwiched between metal layers, offering excellent vibration control across a wide temperature range. They are particularly useful in applications where passive damping is insufficient.

Magneto-rheological (MR) dampers contain fluid with metallic particles suspended in it. When subjected to a magnetic field, the fluid's viscosity changes, allowing for adjustable resistance levels. This technology offers unparalleled control over damping characteristics, making it ideal for applications requiring precise motion control.

While metal dampers have significantly contributed to improving the efficiency and durability of mechanical systems, challenges remain, particularly in terms of their integration into smaller and more complex devices. The future of metal damper technology lies in overcoming these challenges through innovation in materials and design, paving the way for smarter, more adaptable damping solutions.

In conclusion, metal dampers are indispensable components that play a critical role in the realm of mechanical engineering. Through their capacity to reduce vibration, control movement, and convert kinetic energy into heat, they enhance the performance and longevity of machinery across various sectors. As technology advances, the development of more sophisticated metal dampers promises to further revolutionize the control of motion and vibration in mechanical systems.

In embracing the future, it’s crucial to remain at the forefront of these innovations. The ongoing research and development in metal damper technology hold the key to unlocking even greater efficiencies and capabilities, ensuring that mechanical systems can operate more smoothly, safely, and efficiently than ever before.

Understanding and leveraging the full potential of metal dampers is vital for engineers, designers, and manufacturers alike. As we continue to push the boundaries of what is possible in mechanical design, metal dampers will undoubtedly remain a cornerstone of innovation in vibration control.

At its essence, the exploration of metal damper technology is a journey towards achieving optimal performance and sustainability in mechanical systems. As this journey unfolds, it promises to unveil new horizons in mechanical engineering, propelling us towards a future where machinery operates in harmony with the laws of motion and energy, creating a world where efficiency and durability go hand in hand.