If you are interested in our products ,please contact our team

Gas springs have come a long way since their inception, and they continue to be a critical component in various industries, offering precise control, safety, and reliability. As technology advances, so do gas springs. In this article, we'll explore the exciting innovations and advancements shaping the future of gas springs.

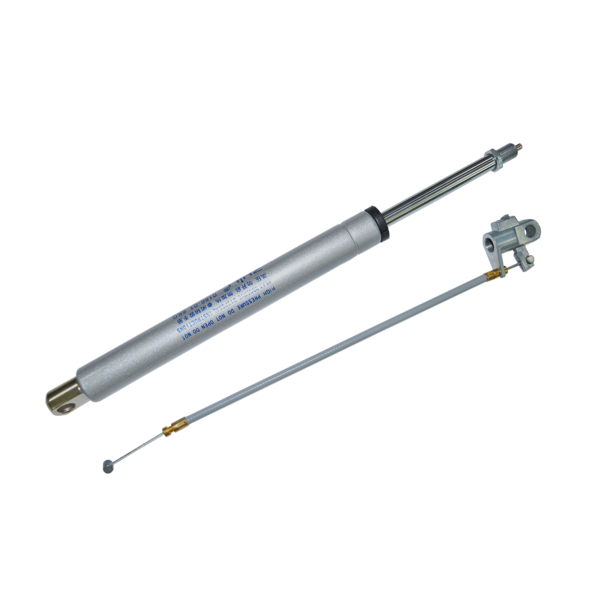

Traditional gas springs have been a staple in industries such as automotive, aerospace, and furniture. They provide controlled linear motion using compressed gas, making them invaluable for tasks like lifting, lowering, and damping.

The future of gas springs lies in "smart" or "intelligent" gas springs. These innovative components incorporate sensors and technology to provide real-time data and enhance performance. For example, they can monitor forces, temperatures, and adjust pressure as needed for optimal operation.

Advancements in materials science have led to the development of lightweight gas springs. These springs are not only strong and durable but also reduce the overall weight of applications, contributing to fuel efficiency in automotive and aerospace industries.

Gas springs are increasingly being equipped with advanced coatings that provide excellent corrosion resistance. This ensures that they can operate reliably even in harsh environments, such as marine and offshore applications.

Future gas springs will likely feature integrated safety sensors that can detect anomalies in real-time, alerting operators to potential issues before they escalate. This added layer of safety is crucial in applications where precision and safety are paramount.

Innovations in gas spring design may include fail-safe mechanisms that can automatically engage in the event of a malfunction, preventing accidents and minimizing damage.

In the healthcare industry, gas springs will continue to play a vital role in patient care equipment, such as hospital beds and surgical tables. Innovations in gas spring technology will lead to quieter and more efficient medical equipment.

In aerospace and aviation, gas springs will become even more critical for lightweighting and optimizing aircraft components. Smart gas springs will provide real-time data for maintenance and performance improvements.

As sustainability becomes a global priority, gas spring manufacturers are focusing on eco-friendly designs. This includes the use of sustainable materials and designing gas springs with a focus on recyclability.

Gas springs will continue to contribute to energy efficiency in various applications. For instance, gas springs with energy recovery systems can capture and reuse energy during compression and extension, saving power and reducing overall energy consumption.

In conclusion, the future of gas springs is a promising one, with innovations and advancements that will further enhance their versatility and reliability across industries. From smart gas springs that provide real-time data to lightweight and eco-friendly designs, these advancements will continue to optimize industrial processes, improve safety, and reduce environmental impact.

At the forefront of gas spring innovation is Zhili Gas Spring, committed to delivering cutting-edge solutions that meet the evolving needs of industries. As technology continues to shape the future, you can trust us to provide gas spring solutions that drive your applications to new heights of performance and efficiency. Contact us today to explore the latest innovations in gas springs and stay ahead of the curve.