If you are interested in our products ,please contact our team

Most people think of a coil of metal that can shrink when it is under tension and then rebound back to its original condition when the tension is released once they encounter the term "spring."

Although this is a typical design for springs, not all springs have this pattern. The two most popular forms of springs are mechanical and gas. There are other types of springs as well.

What precisely separates mechanical springs from gas springs, then? That is exactly what we shall be sharing with you in this blog post.

Mechanical springs are regular coiled metallic springs that, when pressured, store power. A mechanical spring deforms by shrinking to a smaller height when pressure is applied to it.

The mechanical spring will still have energy stored in it when it is deformed. The mechanical spring returns to its original height when the pressure is released thanks to the energy it has stored inside.

Every mechanical spring has an elastic limit or the maximum amount of deflection it can undergo under tension without snapping. Although mechanical springs can be squeezed over their elastic limit, doing so frequently leads to long-term damage.

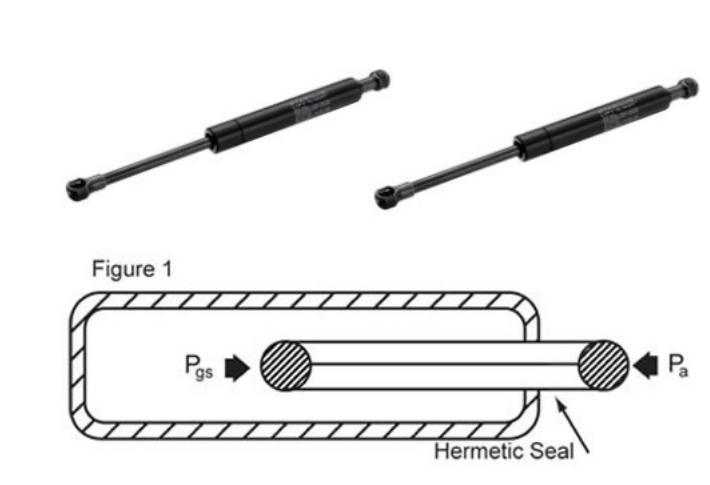

Gas springs are made to store energy, just like mechanical springs, but they go about it differently than their mechanical counterparts. Gas springs use pressurized gas to store energy, as opposed to mechanical springs, which depend on physical deformation.

They have a cylinder-shaped container with a set pressure inside of which inert gas is kept. By pushing on the rod, the pressured gas produces energy akin to that of a typical mechanical spring. Gas springs come in a wide range of designs with an equal range of features.

For instance, some gas springs have a locking mechanism that enables businesses to lock the gas spring in its fully extended state. Naturally, businesses have the option to unlock the gas spring and put it back in its folded, non-extended configuration.

Gas springs are better able to retain and exert energy than mechanical springs. Even while larger gas springs are employed in the manufacturing sector, some of the smaller ones may still exert up to 40 tons of pressure.

It's also important to note that some gas springs have a degressive construction, which means that when the cylinder expands, they apply more force. Due to the flexibility of gas springs, businesses can select end fittings, end caps, and other parts according to their intended output force.

This amount of personalization is typically not available with mechanical springs. Instead, businesses are only able to select from a handful of simple mechanical spring designs.

Please get in contact with us if you wish to purchase mechanical or gas springs, if you have any questions, or if you want more details about our products.