News

Site Editor

Site

https://zhiligasspring.usa72.wondercdn.com/uploads/image/6178b11c16e2d.png

Gas springs, also known as gas struts or shocks, are versatile devices in various applications requiring controlled movement, support, or locking mechanisms.

Site

https://zhiligasspring.usa72.wondercdn.com/uploads/image/6178b11c16e2d.png

Gas springs, also known as gas struts or shocks, are versatile devices in various applications requiring controlled movement, support, or locking mechanisms.

A brief overview of the types of gas springs

Views: 484

Author: Site Editor

Publish Time: 2024-01-03

Origin: Site

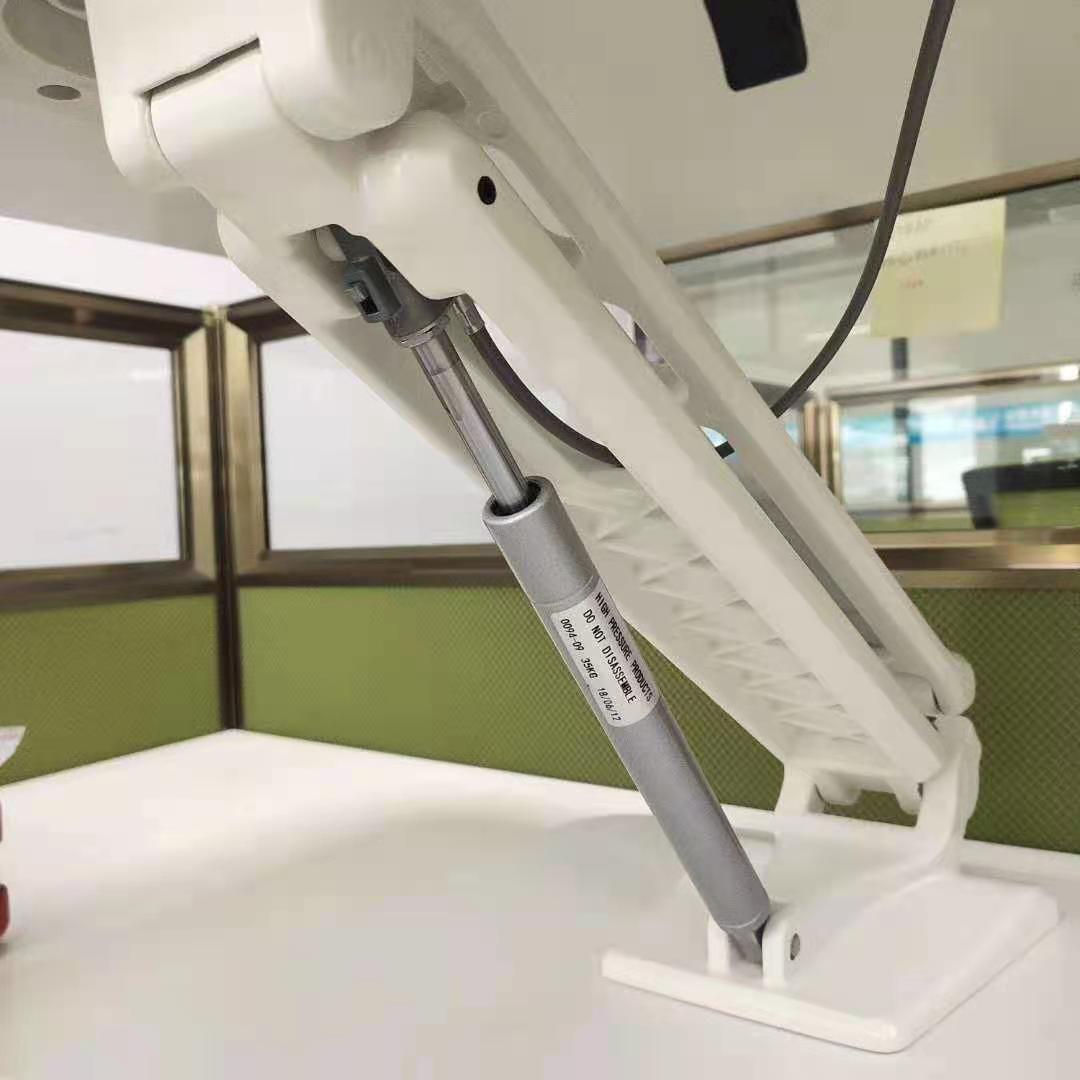

Gas springs, also known as gas struts or shocks, are versatile devices in various applications requiring controlled movement, support, or locking mechanisms. These springs use compressed gas to provide consistent force, making them ideal for lifting, lowering, and counterbalancing tasks.

Several gas springs are available in the market, each designed to cater to specific requirements and applications. Let's explore some of the most common types:

-

Standard gas springs are the most widely used gas springs and come in various sizes and force capacities. Standard gas springs consist of a sealed cylinder filled with nitrogen gas and a piston connected to a rod. When force is applied to compress the spring, the gas is compressed. As the pressure is released, the gas expands, providing controlled movement.

-

Locking gas springs: Locking gas springs are designed to hold the position of an object once it reaches a specific point. These springs have an internal locking mechanism that can be engaged or disengaged using a release mechanism. Locking gas springs are commonly used in applications such as adjustable chairs, hospital beds, or automotive hoods that must be securely placed once opened.

-

Adjustable gas springs: Adjustable gas springs allow for the adjustment of the force exerted by the spring. These springs have a valve or control knob that enables the user to adjust the pressure inside the cylinder to achieve the desired point. The adjustability of these gas springs makes them versatile and suitable for applications where different force levels may be required.

-

Stainless steel gas springs: These are made from stainless steel, making them highly corrosion-resistant and suitable for harsh environments. Stainless steel gas springs are commonly used in marine applications or industries requiring strict cleanliness standards, such as food processing or medical.

-

Traction gas springs: Traction gas springs, also known as traction struts, are unique because they can operate in both compression and tension modes. They are designed to pull and push forces. They are commonly used in applications that require both extension and compression forces. Traction gas springs are used in heavy machinery, truck beds, or caravans.

-

Dynamic gas springs: Dynamic gas springs are specifically designed to have variable force characteristics. They provide different levels of force throughout the spring's travel, making them suitable for applications where variable force control is required. Dynamic gas springs are commonly used in ergonomic seating, fitness equipment, or adjustable industrial machinery.

-

End Fittings: Gas springs have various end fittings to accommodate different installation requirements. These fittings include ball sockets, eyelets, brackets, or mounting flanges.

It's important to note that proper installation, maintenance, and regular inspections are crucial for the safe and efficient operation of gas springs. Following the manufacturer's guidelines and recommended practices ensures longevity and optimal performance.

In conclusion, gas springs come in various types to cater to different applications and requirements. Understanding the various types of gas springs available allows you to make an informed decision when choosing the correct spring for your specific needs. Whether you require standard gas springs for general use, locking gas springs for secure positioning, or adjustable gas springs for flexibility, a gas spring type is available to suit your needs.